A Fully Integrated Metal AM Solution Unlike Any Other

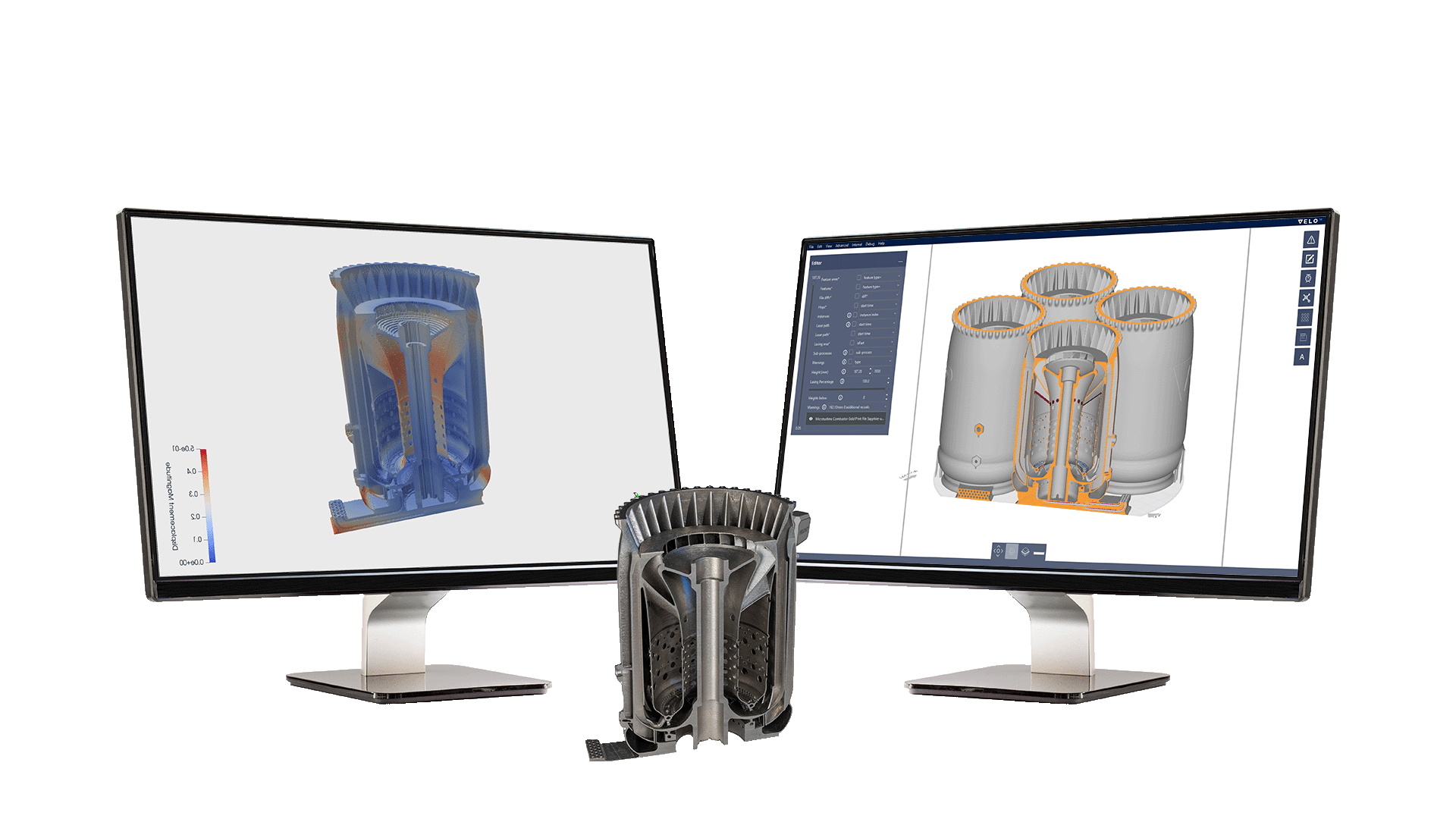

Velo3D has developed a fully integrated manufacturing solution comprised of software, hardware, & an intelligent underlying manufacturing process allowing engineers to build mission-critical parts.

Fully Integrated Solution for Unprecedented, Production-Ready Results

The Velo3D metal AM solution unlocks design freedom for innovative parts. It consists of Flow print preparation software, the Sapphire family of metal 3D printers, Assure real-time quality validation and control software, and is enabled by our underlying manufacturing process.

Flow Software

Flow print preparation software is responsible for prescribing the manufacturing process for the Sapphire printer family.

Watch a short overview of Flow below.

Native CAD Support for a Simpler Workflow

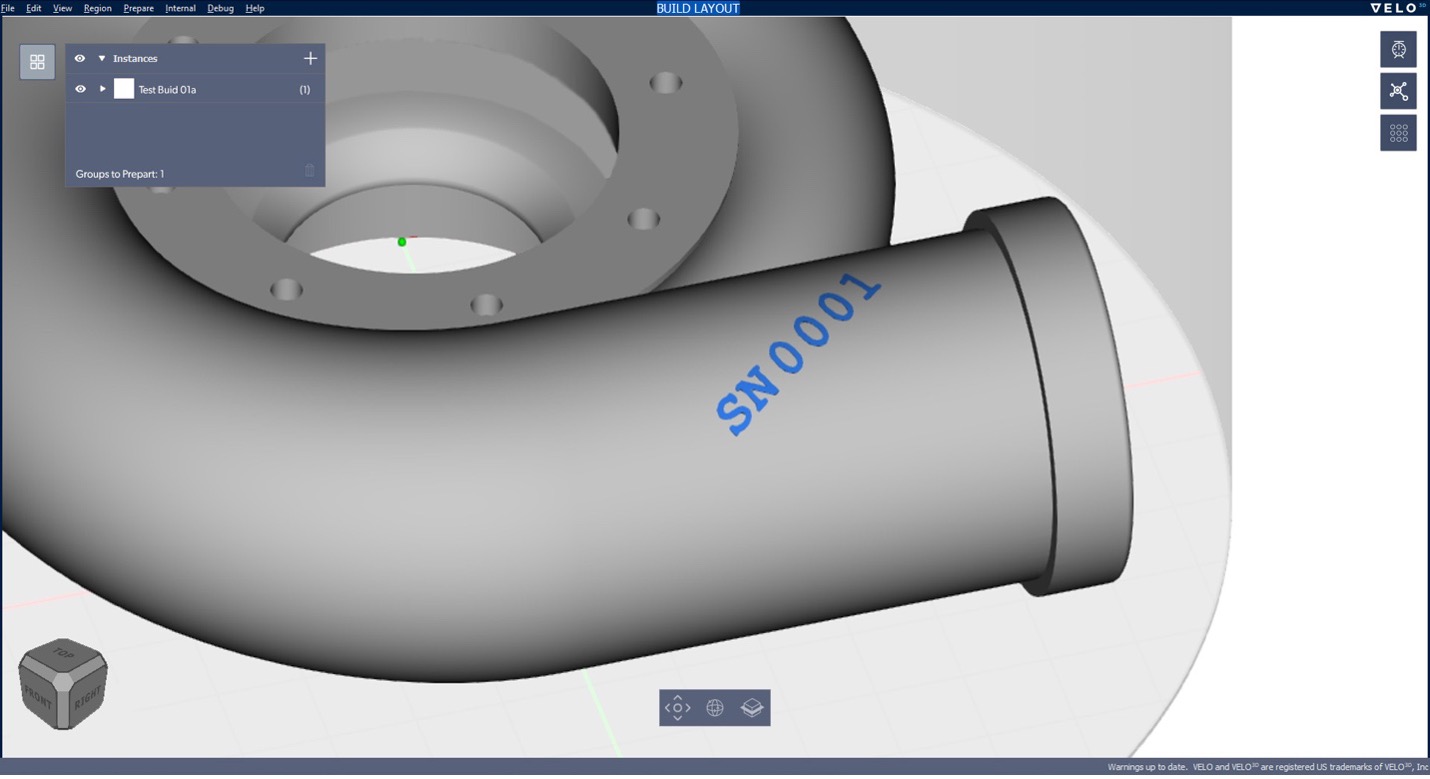

With Flow, you can easily import native CAD models without converting them to labor-intensive STL mesh file formats. This creates greater process control and leads to more consistent outcomes. Flow also enables easy manipulation of the part file to support, orient, layout, and add labels and serial numbers to the part.

Transfer Your Knowledge and Achieve Scale

Flow enables users to accurately print many of the most aggressive engineering designs without the need for feature-based parameter development. Flow can help users achieve their target material properties by assigning different core instructions to parts within the same build or you can utilize Flow Developer, an optional feature of Flow, which enables engineers to determine the optimal process for their application by unlocking the ability to transfer or create their own parameter sets into Flow. This eliminates the need to restart projects, granting access to Sapphire printers’ control, quality, and repeatability allowing engineers to achieve their program goals.

Flow PanX Integration for First Print Success

Velo3D’s integration with PanOptimization takes the guess work out of metal AM by simulating the thermomechanical behavior of the printed part. Quickly highlight issues related to temperature, stress, and distortion for parts of any printable size.

Create a Velo3D “Golden” Print File

Leverage a digital inventory where qualified parts have a persistent, unmodifiable, secure, digital print file (or “Golden” print file) that can be transmitted to a Velo3D-enabled global print facility and recreated to match original specifications.

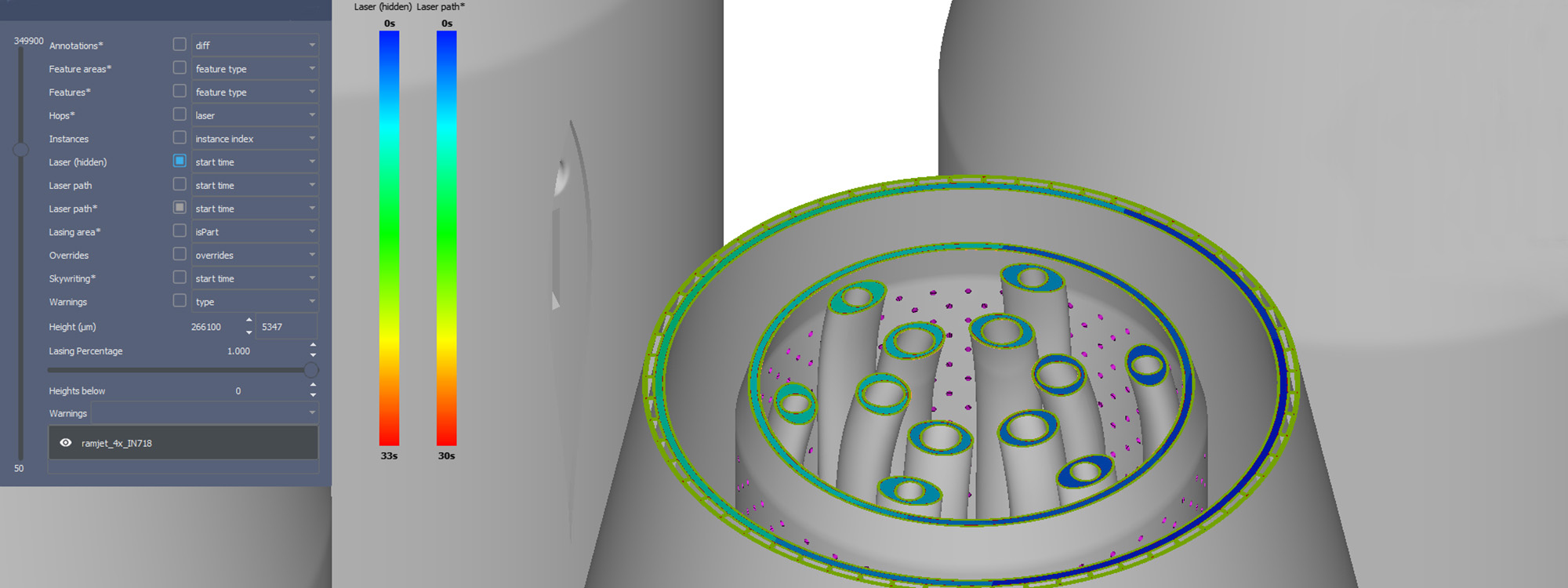

Inspector

No matter how you slice it, Flow’s Inspector gives you a deep understanding of the process before a print starts. This provides a powerful tool to review laser sequencing and parameter assignment. See exactly how Flow’s parameter sets are being applied to your part with detailed information on parameters and laser sequencing.

Native CAD Support

Consistent Properties

PanX Integration

“Golden” Print File

Inspector

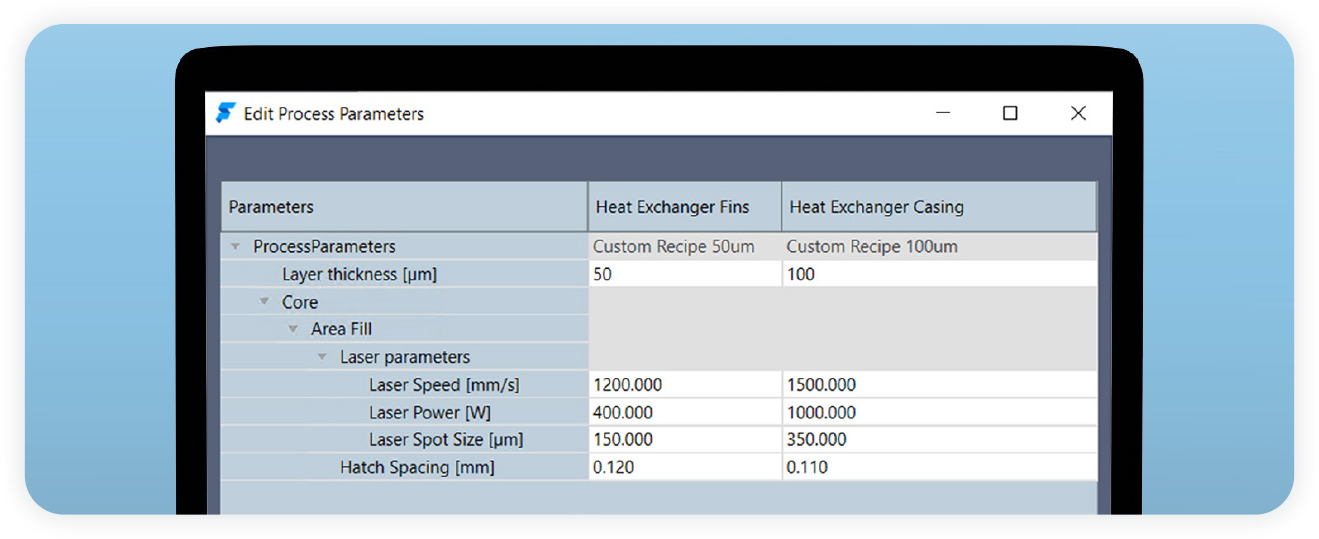

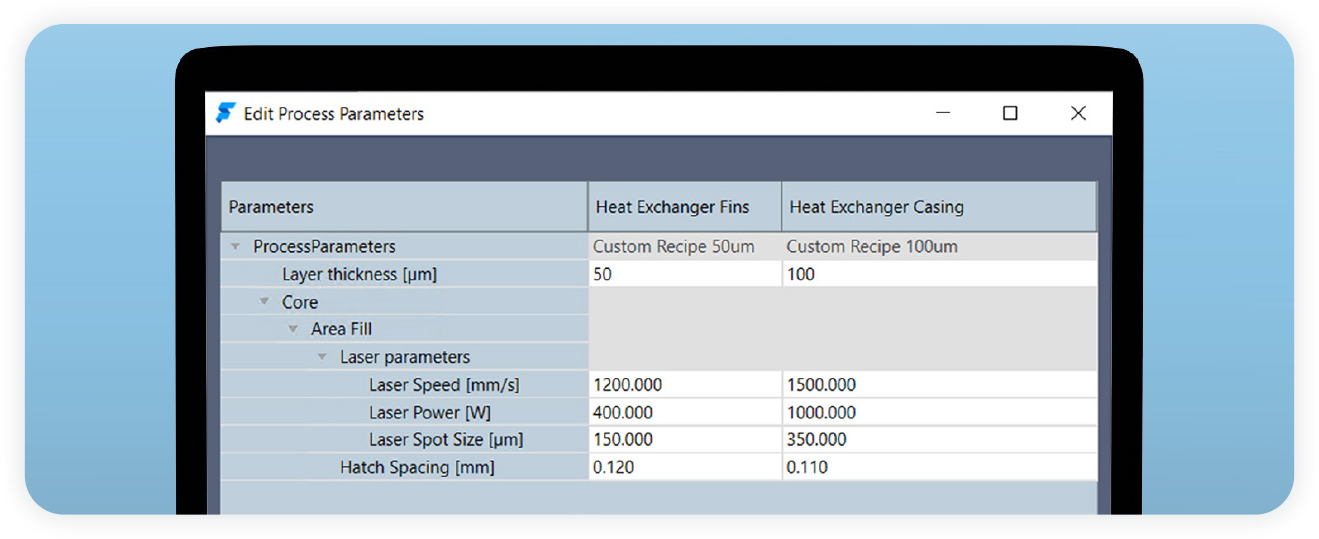

Flow Developer

Flow Developer enables engineers to determine the optimal process for their application by unlocking the ability to transfer or create their own parameter sets into Flow. This eliminates the need to restart projects, granting access to Sapphire printers’ control, quality, and repeatability allowing engineers to achieve their program goals. Users now have maximum flexibility, visibility, and control with the power to create, modify, and inspect processes all within one software platform.

Transfer Your Knowledge and Achieve Scale

Bring your expertise to the Sapphire ecosystem and reproduce your proven processes at scale. Achieve better and more repeatable print outcomes with Velo3D’s automated calibrations, high precision laser controllers, non-contact recoater, advanced metrology, quality assurance, and more.

Control Your Optimization Objectives

Improve the business case for your application through productivity optimization. For parts where throughput is the highest priority, leverage the flexibility to use thicker layers in any material and speed up the print time. For parts where higher feature resolution or different material properties are required, customize to achieve the design intent.

Obtain Full Process Transparency

Combined with Assure’s quality control and build report summaries, Flow Developer unlocks the most comprehensive view of the manufacturing process for each application. This enables companies to integrate AM into their engineering and manufacturing processes.

Develop New Material Processes

Access new markets and opportunities through new material development at the rate of your business needs. Explore novel solutions as they become available in the market and create corresponding parameter sets to serve specific applications.

Transfer Knowledge & Achieve Scale

Control Your Objectives

Full Transparency

Sapphire Printers

State-of-the-Art 3D Metal Printers

Our next-generation Velo3D Sapphire family of printers all use the same software, run the same process, and use the same materials ensuring repeatable consistency across the fleet. Engineered to meet your design, performance, and quality requirements, our printers continually monitor and control the build layer-by-layer for predicable and efficient production. The outcome results in complex part geometries for real-world applications.

Unlike conventional AM printers, the Sapphire printers utilize a proprietary protrusion tolerant non-contact recoater that almost eliminates the risk of part collisions, dramatically improving yields and facilitating a printing process enabling lower angles and overhangs down to zero degrees, thin leak tight walls, large diameter and extremely small inner tubes, with little or no supports.

Features

Laser and Optics Fidelity

Run-time and one-click optics calibrations

Self-cleaning laser windows

Powder Bed Uniformity

Non-contact recoater

Per-layer 3D powder bed height mapping

Full-height printing without interruption for powder addition or filter changes

Environmental Control

Sub-10 ppm O2 during normal operation

Active humidity monitoring

Ambient temperature and pressure operation

Highly regulated chamber gas flows

High efficiency spatter removal

Sapphire & Sapphire 1MZ Printers

315mm Ø x 400mm z

315mm Ø x 1000mm z

Sapphire XC & Sapphire XC 1MZ Printers

600mm Ø x 550mm z

600mm Ø x 1000mm z

Velo3D’s Non-Contact Recoater

Velo3D’s proprietary non-contact recoater allows for the creation of complex, intricate designs while reducing defects and build failures.

Assure Software

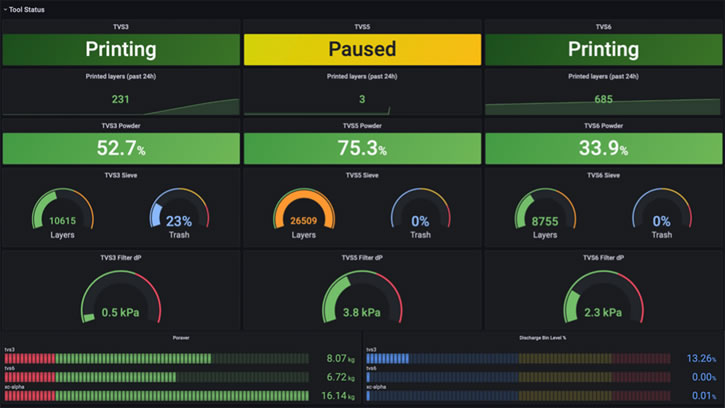

Velo3D’s Assure Quality Software offers comprehensive factory monitoring, providing real-time tracking of machine fleet and live build progress status for effective oversight of factory performance. Integrated with Grafana, engineers can customize graphs and dashboards using nearly 1,000 sensor readings, offering detailed insights into the process. Automated system calibrations ensure replication of parts within geometric and material property specifications, with Assure recording printer calibration history to swiftly identify issues and trends. In-process monitoring offers an overview of build performance data, including optical health and powder bed quality, allowing users to delve into specification compliance. Additionally, build history reporting simplifies access to historic records and critical build information, offering on-demand summaries of tool calibration status, interrupt reporting, and height mapper images. Learn more below.

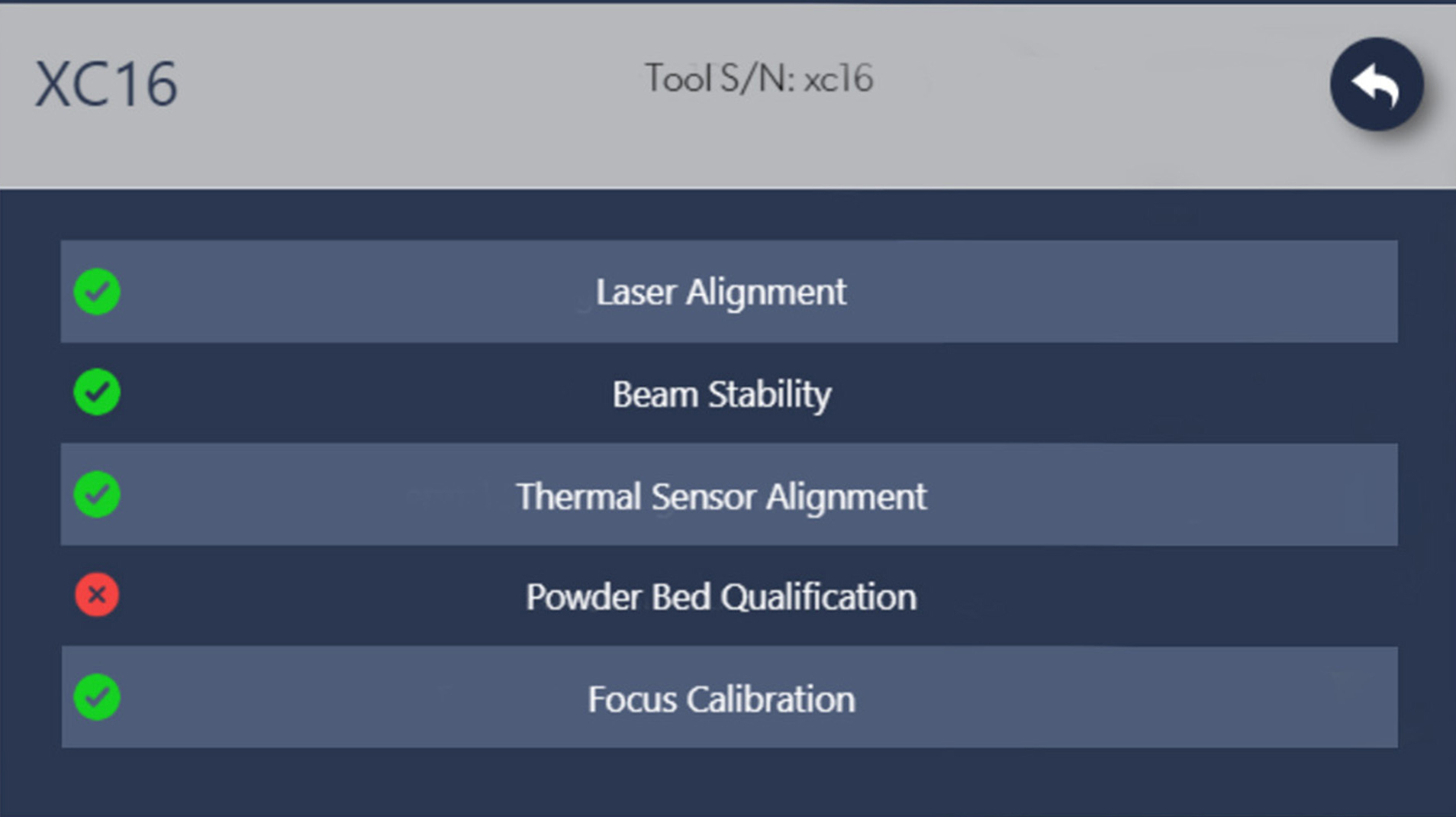

Pre-Print Calibrations

Assure displays Sapphire’s automated calibration results that ensure consistent geometric accuracy, surface finish, and validated material properties year-to-year and system-to-system. These in-situ calibrations can be run directly by the user from the printer control screen with no added equipment in a runtime environment. Results of these routines are displayed on Assure and archived for the life of the system for future reference. The main checks composing the Tool Health Checklist (THCL) include: powder bed qualification, focus calibration, laser alignment, thermal sensor alignment, and beam stability.

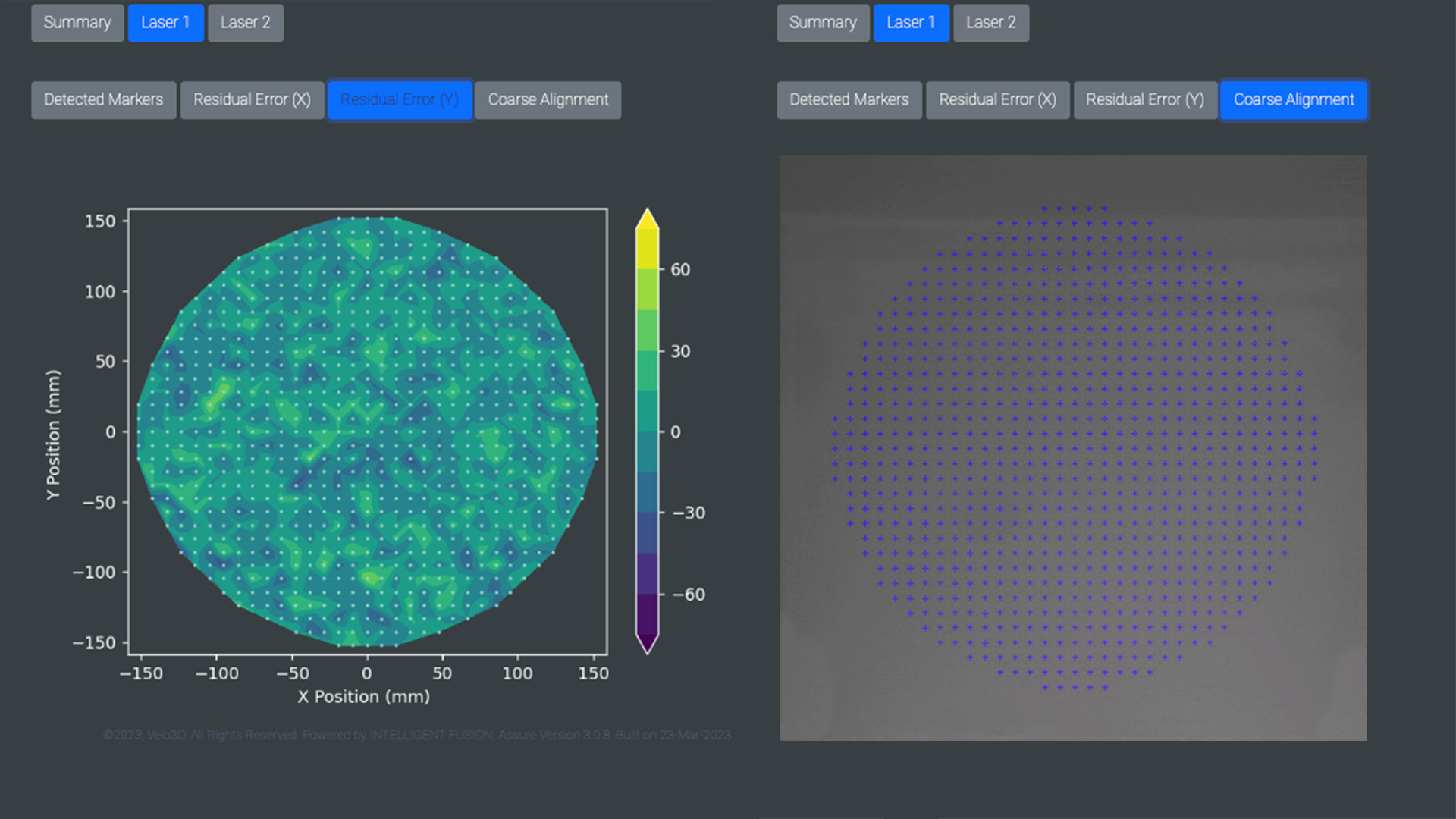

Multi-Laser Alignment

Pre-build, in-situ alignment ensures high quality overlay between lasers. This fully automated calibration routine runs without additional equipment and validates alignment at multiple locations on the build plate. Additional run-time checks quickly validate alignment every layer making on the fly adjustments if necessary. This improves surface finish by removing part stitch lines and helps to eliminate overlay porosity due to mismatch.

Process Monitoring

During the process, Assure tracks a layer-by-layer validation of atmosphere, consumables, and powder bed health to enable part quality. Throughout the print, factors like oxygen and humidity are tracked to verify that material properties stay consistent. By monitoring consumable indicators, like filter life and powder levels, Assure helps to prevent unexpected interrupts. Lastly, the system continually monitors for part protrusions that can occur due to excessive stress or build set up issues.

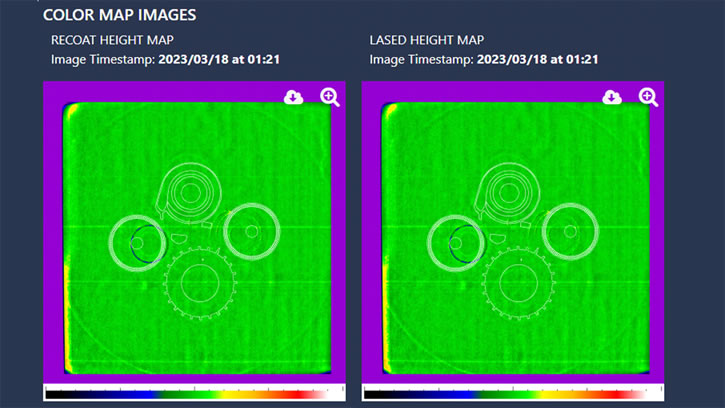

Height Mapper

Provides a detailed, layer-by-layer view of powder bed quality and lasing behavior. Height Mapper is a 3D structured light scanner that reveals powder bed topography and ensures a conformal powder bed prior to and after each layer. A very powerful tool for troubleshooting a build, this process checks for target layer thickness, smoothness, and part protrusions.

Grafana Integration for Enhanced Transparency

Assure integrates with Grafana giving engineers access to the nearly 1,000 different sensor readings that monitor the printing process. Gain detailed insights and manage the key variables governing your additive part production.

Pre-Print Calibrations

Multi-Laser Alignment

Process Monitoring

Height Mapper

Grafana Integration

Materials

Empower your engineering goals with the dynamic capability of the Sapphire family of printers, offering a versatile range of materials tailored to specific needs and use cases. Unleash creativity and achieve unparalleled project success.

Aheadd® CP1

Aheadd CP1 is Constellium’s new high-performance Aluminum-Iron-Zirconium powder, designed for laser powder bed fusion. Aheadd CP1 brings high strength and ductility, excellent thermal and electrical conductivity, high productivity LPBF processing, and simplified post-processing.

Ideal for heat transfer applications in the motorsport, defense and aerospace industries.

Aluminum F357

A foundry-grade beryllium free aluminum-silicon alloy. It has excellent weldability and corrosion resistance and is heat treatable to T5, T6, and T7. It is a lightweight, corrosion resistant, and highly dynamic load-bearing material.

Ideal for heat transfer in the defense and automotive industries.

forAM® Haynes® 282®

A gamma-prime strengthened superalloy developed for high temperature structural applications, especially those in aero and industrial gas turbine engines. It possesses a unique combination of creep strength, thermal stability, weldability, and fabricability.

Ideal for high temperature applications such as gas turbine and power/process industry parts.

Copper

GRCop-42

A copper-chromium-niobium alloy, developed by NASA to additively manufacture parts in need of high-strength dispersion and high conductivity. It retains strength at temperature, has excellent creep resistance, and a low cycle fatigue life.

Valuable for rocket engine components such as fuel injector faces and combustion chamber linings with regenerative cooling.

Hastelloy® C22

An alloy containing chromium, molybdenum, tungsten, and iron, making the alloy resistant to seawater corrosion with excellent weldability. Resistant to both uniform and localized corrosion and a variety of mixed industrial chemicals. Superior pitting, crevice attack, and stress corrosion cracking.

Used in corrosive environments with high chloride and high temperature conditions, such as flue-gas scrubbers, nuclear fuel re-processing, sour gas handling, and pesticide production.

Hastelloy® X

A nickel-chromium-iron-molybdenum alloy that is corrosion resistant. It possesses excellent forming and welding characteristics and is easy to fabricate with localized corrosion resistance and oxidation resistance up to 2200° F (1200° C).

Used in high temperature and corrosive atmosphere applications. Commonly used in gas turbines, energy generation applications such as transition duct, combustor cans, afterburners, and spray bars.

Haynes® 214

A nickel-chromium-aluminum-iron alloy designed to provide the optimum high-temperature oxidation resistance, while at the same time allowing for conventional forming and joining. This alloy offers outstanding oxidation resistance to 2300° F (1260° C).

Ideal for high temperature, oxygen rich environments including turbo-machinery components found in rocket engines.

Inconel® 625

A nickel-based superalloy that possesses high strength properties and resistance to elevated temperature. Shows remarkable protection against corrosion and oxidation. It has an ability to withstand high stress over a wide temperature range, both in and out of water, as well as resisting corrosion while exposed to highly acidic environments.

Ideal for nuclear energy and marine applications.

Inconel® 718

A precipitation-hardenable nickel-based alloy known for superb tensile strength under extreme pressure and heat. It has rupture strength at temperatures up to 1290° F (700° C), and is characterized by its superb fatigue, creep and corrosion resistance in extreme environments.

Ideal for applications in gas turbine and power/process industry parts in aerospace, defense, and chemical industries.

M300 Steel

M300 Steel is an ultra-low carbon alloy with very high strength and hardness properties derived from intermetallic compounds rather than carbon content. The material is comprised mainly of nickel, with cobalt, molybdenum, and titanium as secondary intermetallic alloying metals.

Ideal for tooling applications such as High Pressure Die Cast (HPDC) inserts, injection molding, and other types

of tooling.

Scalmalloy®

Made from scandium (Sc), aluminum (Al) and magnesium (Mg), it is the only AM alloy which substitutes

for high strength 7000-series aluminum. It has outstanding properties in terms of weldability and low thermal expansion, and is well-suited for anodizing processes and offers good corrosion resistance.

Ideal for highly loaded, safety-critical parts exposed to high mechanical stress and which are required to be light weight.

Stainless 415

Stainless Steel 415 is a chromium-nickel stainless steel with additional molybdenum. Stainless 415 exhibits high mechanical properties due to the concentration of molybdenum and nickel. Its molybdenum content also provides basic pitting and crevice corrosion resistance.

The combination of good corrosion resistance and excellent strength and toughness makes it a perfect candidate for mechanically highly stressed components in wet corrosive environments.

Titanium 6AI-4V

An alpha-beta titanium alloy characterized by its strength-to-mass ratio and corrosion resistance. It is a strong lightweight alloy suitable for highly loaded structures. Parts built with this alloy on a Velo3D Sapphire printer can be heat treated like other manufacturing methods.

Used in jet engines, gas turbines, pressure vessels, and biomechanical components.